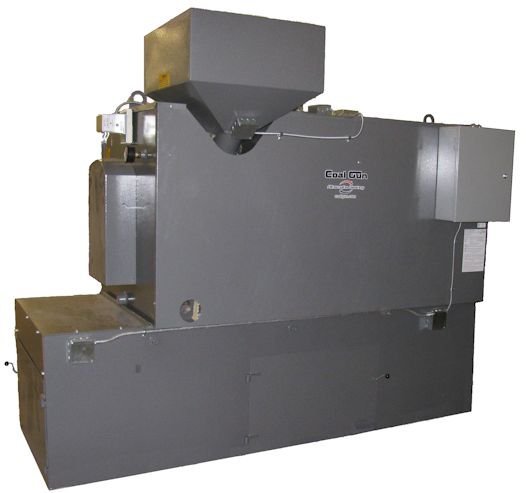

S1000

The S1000 model comes standard with an auto-feed auger controls and belt-driven fan. It offers the highest BTU output of all the Coal Gun units—ideal for large commercial facilities.

Designed to burn Pea or Buckwheat-sized Anthracite coal, each Coal Gun unit ensures minimal labor, nominal expense, maximum fuel efficiency, and marathon burn-time.

The Coal Gun is nearly 100% automated. You can be confident that your boiler is burning at optimum efficiency, without having to make ongoing adjustments. Our signature Thermo Ash-Monitoring Control System automatically regulates burn rate and air intake, ensuring that every ounce of coal yields its fullest heat potential. This technology makes it possible for the fire to burn for days at a time, even during low-use periods.

Operation requires only three simple steps…

Add coal, Remove ash, Repeat every 2–7 days (depending on demand)

The most cost-effective stoker boiler on the market, the Coal Gun saves users up to 70% off their heating costs with conventional oil, gas, or electric systems.

With our signature Thermo Ash-Monitoring Control, the Coal Gun ensures that every ounce of coal yields its fullest heat potential before being discarded. This makes it possible for the fire to burn for days at a time, even during low-use periods.

Though designed primarily for use with hydronic boiler systems, the Coal Gun can be adapted to work with forced hot air systems or steam heating applications.

Coal Gun boiler units are made to be the last boiler you’ll ever buy, and require only minimal seasonal maintenance. Built for lifetime durability, many of our units are into their fourth decade of operation.

In addition to the standard 20 year warranty on the full unit, the burn grate in every Coal Gun is covered by an additional lifetime warranty.

- Simple to Use

- Minimal Maintenance

- Cost Effective

- Fuel Efficient

- Versatile Applications

- Lifetime Durability

- Standard ASME Certification

- Standard UL Safety Certification

Call (717) 987-0099 for pricing

BTU/hr

995,000

Approximate Water Capacity (gal)

220

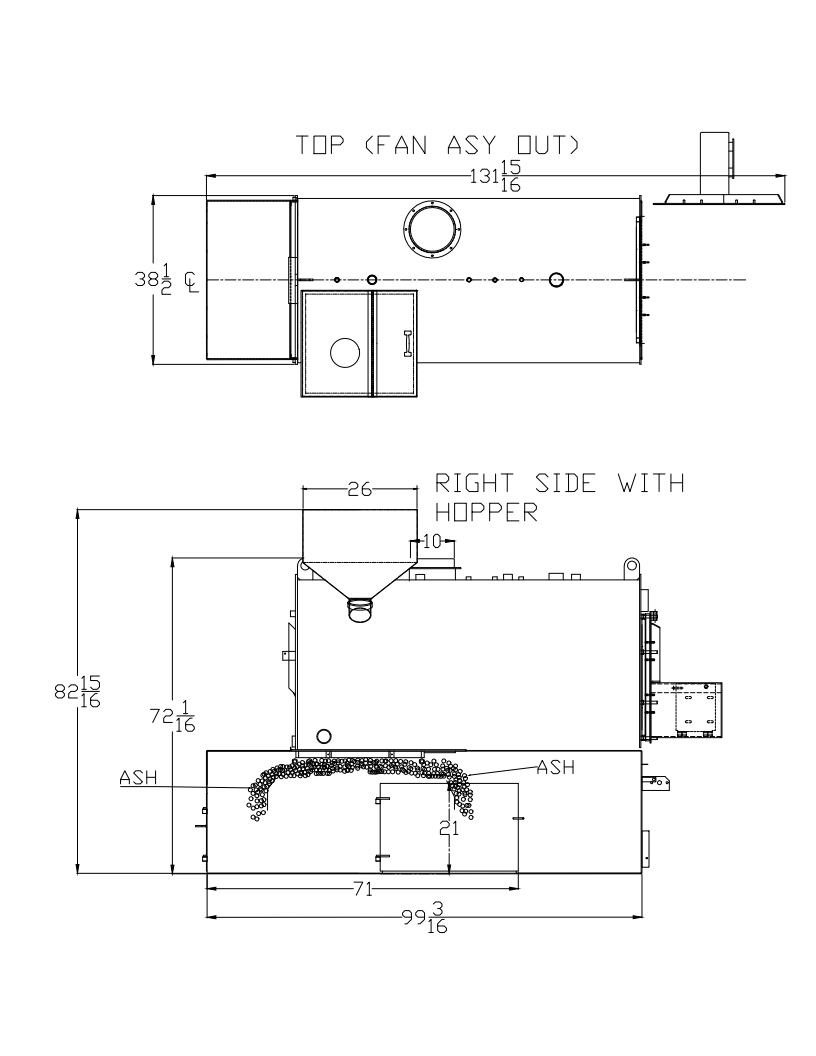

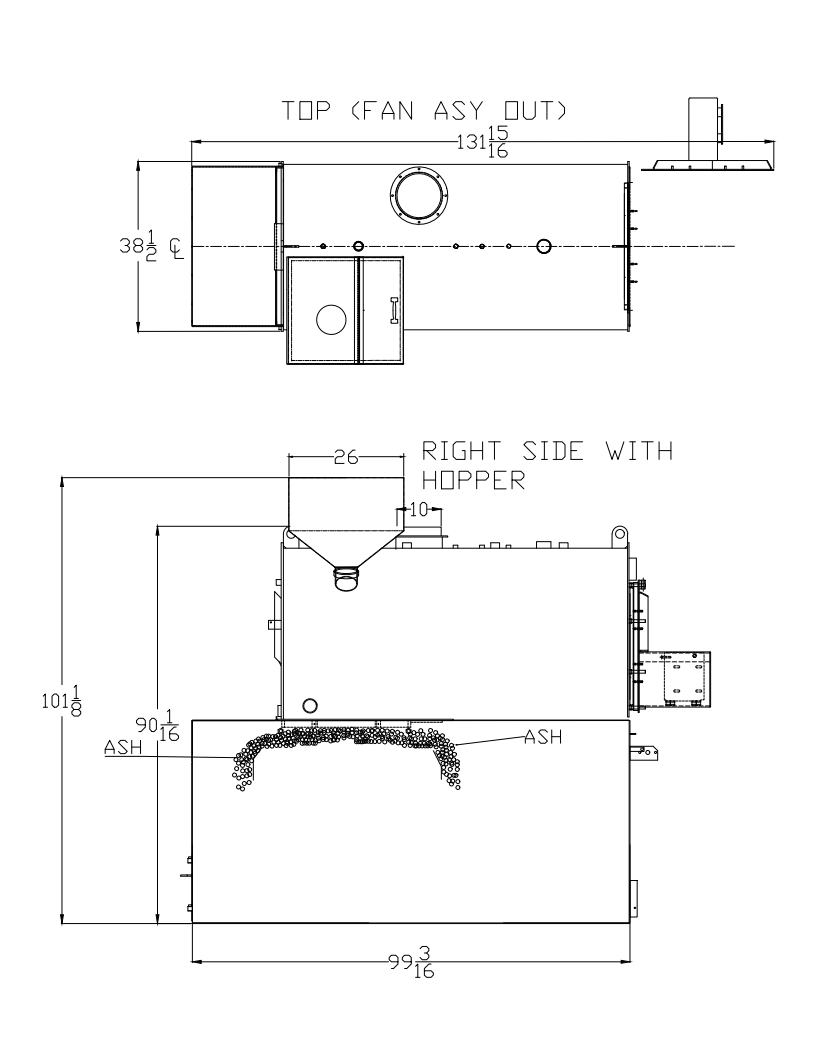

Width (in)

66

Height (top of hopper) (in)

STANDARD- 83 STRETCHED BASE- 101

Length (in)

102

Approximate Weight (lbs)

3,800

Flue Size (in)

10

Return Tapping (NPT) (in)

(2) 2 1/2

Supply Tapping (NPT) (in)

(2) 2 1/2

Auger Loading

The Coal Gun can be enhanced with an auger add-on that eliminates the need to manually fill the hopper. This is especially important on the large models (S500, S1000), as a higher demand for heat requires more regular filling. Auger add-ons have both automatic and manual settings for maintaining coal reserves.

4″ or 6″ Diameter

Your choice of diameter will depend on load size. Auger length can be customized per requirements.

Pulley-Drive or Belt-Drive

The drive method of your auger will be dictated by load size and application. Pulley-driven augers work in scenarios where there is little change in elevation between coal bin and hopper. Belt-driven augers are preferred in situations where elevation varies.

Auger Inlet Guard

An auger inlet guard provides added safety. The guard’s sturdy mesh screen prevents unwanted objects from contacting the auger screw.